Engineering > PROJECT FINAL > UNDERGROUND BLAST DESIGN FOR GEMSTONES MINING; FOR EFFICIENT AND SAFE EXCAVATIONS. (FINAL YEAR PROJE (All)

UNDERGROUND BLAST DESIGN FOR GEMSTONES MINING; FOR EFFICIENT AND SAFE EXCAVATIONS. (FINAL YEAR PROJECT)

Document Content and Description Below

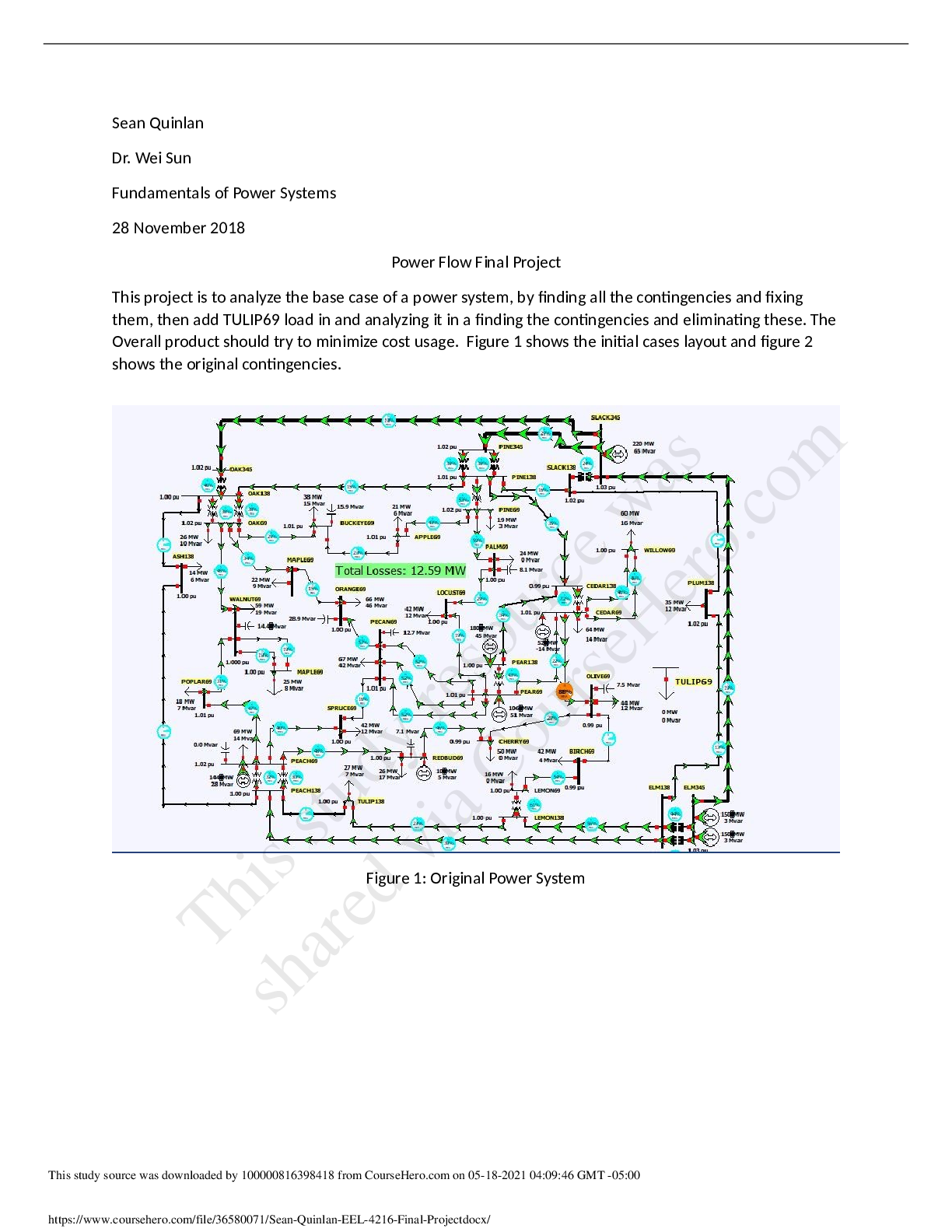

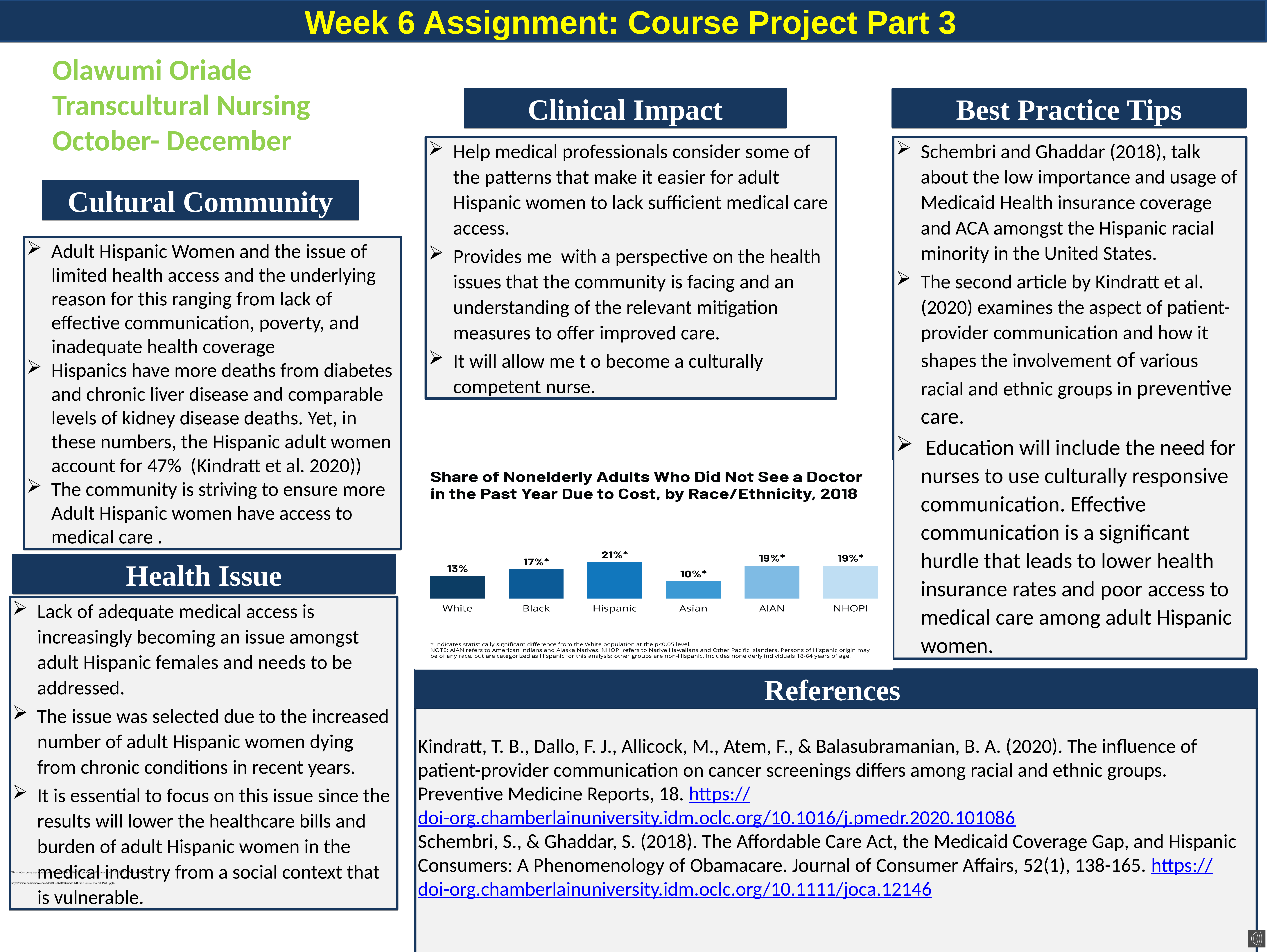

FINAL YEAR PROJECT UNDERGROUND BLAST DESIGN FOR GEMSTONES MINING; FOR EFFICIENT AND SAFE EXCAVATIONS. CASE STUDY; KASIGAU GEMSTONES MINES FINAL PROJECT PRESENTED TO THE DEPARTMENT OF MINING, MATE... RIALS AND PETROLEUM ENGINEERING. PROJECT CODE: MMPE-PRO-20-06 Presented by IN PARTIAL FULFILLMENT FOR THE AWARD OF BACHELORS DEGREE IN MINING AND MINERAL PROCESSING ENGINEERING DECEMBER 2020 DECLARATION We declare that this is our original work of the project submitted and to the best of our knowledge, this work has not been submitted anywhere in any university for the award of any other Degree. Name Signature: …………………… Date: ………………………… Name Signature: …………………… Date: ………………………… SUPERVISOR APPROVAL I hereby declare that I have checked this project and, in my opinion, it is adequate in terms of scope and quality for the award of marks. Name of Supervisor:. Signature: ………………………………… Date: ……………………………………… ABSTRACT Rock fragmentation in both underground and surface mining is achieved by drilling and blasting. This method has undergone tremendous developments from the use of black powder in the earliest days to modern explosives with efficient detonating and delay techniques. Underground blasting is different from surface blasting in that there is no free face from which to blast from. This limits the length and the volume of round to be blasted. A cut blast is thus required to produce a room from which the other holes will stope from. Cut blast is very vital for efficient blast that allows efficient extraction of the ore. However, if done incorrectly the blast will not go off well and sockets result on the face slowing the rate of advancement of the workings. This led as to carry out a study to come up with a drilling and blast design that will produce a successful cut blast to ensure fast extraction speed, avoid financial losses and accidents associated with misfires at Kasigau gemstone mines. In this project, we focused our attention on Kasigau Gemstone mines located in Taita Taveta County. We analyzed rock properties, drilling and blasting parameters in order to come up with a blast design that will ensure efficient and safe excavations. TABLE OF CONTENTS DECLARATION i SUPERVISOR APPROVAL ii ABSTRACT iii LIST OF FIGURES vii LIST OF TABLES viii CHAPTER 1 1 INTRODUCTION 1 1.1 Research Background 1 1.2 Problem statement 2 1.3 Justification 3 1.4 Main Research Objectives 4 1.4.1 Specific Objectives 4 CHAPTER 2 5 INFORMATION ABOUT STUDY AREA 5 2.1 Location of the mine 5 2.2 Mining Method 5 2.3 Market 5 CHAPTER 3 7 LITERATURE REVIEW 7 3.1 Geology of the Area 7 3.1.1 Economic Geology 8 3.2 Blasting Terminologies 10 3.3 Underground Blasting 11 3.3.1 Wedge cut 11 3.3.2 Pyramid or diamond cut 12 3.3.3 Drag cut 13 3.3.4 Fan cut 14 3.3.5 Burn cut 15 3.4 Drift Face Terminologies 16 3.5 Factors Affecting Drilling and Blasting 18 3.5.1 Rock Characteristics 18 3.5.2 Rock Structure: 18 3.5.3 Explosives Types 20 3.5.4 Sequence of detonation 21 3.6 Designing a blast 21 3.6.1 Determining Hole Size 21 3.6.2 Determining Hole Orientation 21 3.6.3 Determining Round Length 22 3.6.4 Determining Powder Factor 22 3.6.5 Design of a Burncut 23 3.6.6 Design of Perimeter holes 24 3.6.8 Smoothwall Delay Timing 25 CHAPTER 4 26 DATA COLLECTION AND ANALYSIS 26 4.0 Introduction 26 4.1 Equipment used 26 4.2 Data collection procedure 27 4.3 Data Analysis 30 4.3.1 Calculation of blast parameters 30 4.3.2 Estimating the powder factor from the field data 31 4.3.3 Analyzing the cut area 31 4.3.4. Analyzing perimeter holes 32 4.4 Redesigning the Blast parameters based on the data analysis 32 4.4.1 Designing the cut 33 4.4.2 Sequence of detonation 36 4.4.3 Designing the delay time 37 CHAPTER FIVE 39 CONCLUSION AND RECOMMENDATIONS 39 5.1 Conclusion 39 5.2 Sources of error 39 5.3 Recommendations 40 REFERENCES 41 LIST OF FIGURES Figure 1 Map of Taita Taveta 6 Figure 2 Geological Map of Taita Taveta 9 Figure 3 Wedge cut 12 Figure 4 Pyramid cut 13 Figure 5 Drag cut 14 Figure 6 Fan cut 14 Figure 7 Burn cut 15 Figure 8 Drift Face holes 17 Figure 9 Burden measurement 24 Figure 10 The redesigned blast pattern 35 Figure 11 Blast pattern dimensions (mm) 36 Figure 12 Blast pattern sequence of detonation 37 Figure 13 Blast pattern delay times 38 LIST OF TABLES Table 1 Properties of typical rock types (Nobel, 2010) 19 Table 2 SME mining reference handbook 2003 (typical characteristics of commercial explosives) 20 Table 3 Underground Blasting Technology (Heading round powder factor range table) 23 Table 4 Field data 28 Table 5 Prevailing blast data 29 Table 6 General mine information 30 Table 7 Calculation of powder factor 30 CHAPTER 1 INTRODUCTION 1.1 Research Background Underground mining cannot proceed successfully without adopting efficient and safe method of extraction of both ore and waste. This solely depends on the blast design adopted. If the blast design is done wrongly, the rate of advancement will be slowed and possible collapse of the walls due to induced stresses. This will not only lead to financial losses but also the lives of the miners will be put at risk. Successful blast design can be achieved by the in-depth analysis of rock properties, drilling parameters as well as charging and delay times. When these parameters are considered in the design, the mine will experience improved productivity and blasting expenditure will be minimized. In Taita Taveta the artisanal miners lack proper tools and techniques to design a proper blast hence they often experience blast related problems e.g. collapse of shaft walls. For example, on Saturday September 28th,2019, three miners were killed and four injured as reported in Daily Nation. In this project, we examined blast design techniques that are currently being employed there and came up with improved blast design with the benefits mentioned above. 1.2 Problem statement Artisanal and small-scale gemstone miners are exposed to many risks including collapse of mines. At Kasigau, green garnet mines at Dare B have gone to depths of over 100m in narrow and inclined shafts lying along rocks like graphites and gneisses, which are highly fractured. Lack of geological background, poor estimation of burden and spacing and charging of explosives by the artisanal miners has led to undesirable results from blast in most of gemstone mines. The ore has been lost through overbreak, gemstones have been damaged, gases have accumulated and deaths have been reported because of poor blast designs. The miners also lack proper ventilation network and most suffer from accumulation of toxic fumes that result from the blast. The fume class is a measure of the amount toxic gases, primarily CO and NOx produced by the detonation of an explosive. Inadequate priming and improper delay timing are factors that lead to more production of fumes that tend to accumulate for longer periods of time thus slowing down the productivity as well as advancement rate. 1.3 Justification The artisanal miners are growing very fast but their growth is hampered by cases of mine collapse that result from poor blast design. The rate of advancement is also slowed down by the formation of sockets that come as a result spacing cut holes widely thus preventing room for expansion and successive breaking of rocks because the energy released by the explosive will not be enough to break the huge volume of rocks. These drawbacks pose a threat to human life and lead to financial losses. With our improved blast design, the mines can rapidly be developed without the uncertainties described above and production will proceed on smoothly according to mine plan. In this project we have proposed a blast design that will help to counter the problems that are currently experienced. The proposed blast design if implemented will be a guideline by which miners will act to stay within the safety and economic limits. 1.4 Main Research Objectives The main aim of this project was to propose a blast design pattern in the underground drifts that is safe and ensures efficient excavations. 1.4.1 Specific Objectives 1. To determine rock properties and establish how they can be incorporated in the blast pattern design. 2. To determine correct burden and spacing. 3. To determine right delay times that will achieve desired fragmentation. CHAPTER 2 INFORMATION ABOUT STUDY AREA 2.1 Location of the mine The mines are located in Taita -Taveta County in the Kasigau ranches. The area and its neighboring environs have many mineral deposits as per several surveys that have been carried out in the area. 2.2 Mining Method Most artisanal miners use simple tools and techniques to mine which at times exposes them to risks. The area has high and middle value gemstones including; Tsavorite (green garnets), red garnets, ruby, blue and pink sapphire, green tourmalines, yellow tourmalines, rhodolites and kyanites. 2.3 Market The market is dominant with brokers mostly of foreign origin who buy the gemstones from the miners and sell the gems at international market. Tsavorite is among the most expensive of all the garnets, with prices similar to those fetched by the fine demantoid but like all gemstones, low quality pieces may be available for a few dollars per carat. Prices for tsavorite vary greatly according to size.at the international market they may reach as much as US$8000 per carat for high quality piece of tsavorite. The brokers usually exploit the local miners through buying the gemstones at very lower prices and they sell the same at higher intentionally therefore leaving the miners with very little amount of money to purchase modern equipment and machinery required for production purpose. Figure 1 Map of Taita Taveta CHAPTER 3 LITERATURE REVIEW 3.1 Geology of the Area The entire area of Taita Taveta is situated within the Mozambique Belt, a major structural / metamorphic un it that extends along the African east coast from Mozambique and Malagasy into the Sudan and possibly as far north as Egypt and Arabia; it represents one of the fundamental geological features of Africa .The belt consists typically of high-grade metamorphic rocks. Three major units were recognized in southern Kenya (Pohl & Niedermeyer 1979): Relics of older-metamorphic basement occur as wedges and slices of charnockites and granulites, tectonically emplaced within metasediments. Variegatedmio – geosynclinals meta-sediments, consisting of marbles, quartzites, graphite and kyanite (sillimanite) gneisses and schists, biotite (hornblende) gneisses and amphibolites which were deposited as a sedimentary cover with volcanic intercalations upon the basement. Eu–geosynclinals meta - sediments are considered to be represented by a thick suite of monotonous meta-greywackes (quartz feldspar-biotite hornblende gneisses) with bands of ortho-amphibolites, described by Saggerson (1962) as "Kasigau Series" immediately to the east of the Taita area. This unit probably was deposited on a continental margin. Facies transitions between the two series suggest approximate time equivalence. The present contact between the two groups is apparently concordant. It is marked by lenses of meta-dunites, peridodites and –basalts possibly representing dismembered ophiolites along a regional thrust. [Show More]

Last updated: 1 year ago

Preview 1 out of 52 pages

Reviews( 0 )

Document information

Connected school, study & course

About the document

Uploaded On

Apr 13, 2021

Number of pages

52

Written in

Additional information

This document has been written for:

Uploaded

Apr 13, 2021

Downloads

0

Views

83